- GD&T

GENERAL DIMENSIONING- International Paper Size Standards

- Technical Drawing Styles

- ISO And ANSI Projections

- ANSI Technical Drawing Views

- Technical Drawing Dimesioning Types

- ANSI and ISO Geometric Tolerancing Symbols

- Geometric Tolerancing Reading

- Taylor Principle Rule#1

- Form Tolerances

- Profile Tolerances

- Orientation Tolerances

- Location Tolerances

- Runout Tolerances

- TOLERANCES

ANSI AND ISO- Tolerancing and Engineering Standards

- Hole and Shaft Basis Limits And Fits

- ISO International System For Limits And Fits

- International Tolerance Grade (IT)

- Fundamental Deviations For Hole and Shaft Basis

- ISO Tolerance Band IT01-IT16

- Calculation Of International Tolerance

- Calculation of Upper and Lower Deviation For Shaft

- Calculation of Upper and Lower Deviation For Holes

- ISO Shaft Tolerances (3mm-400mm)

- ISO Shaft Tolerances (400mm-3150mm)

- ISO Hole Tolerances (3mm-400mm)

- ISO Hole Tolerances (400mm-3150mm)

- ANSI Standard Limits and Fits

- METAL CUTTING TECHNOLOGIES

- Terms and Definitions of the Cutting Tools

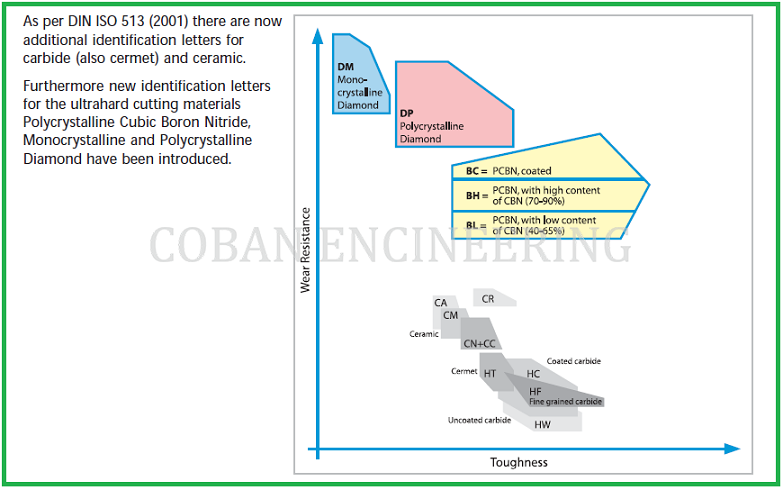

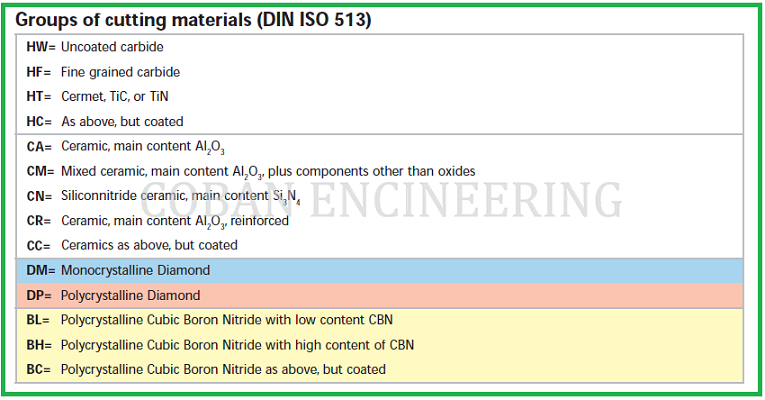

- Cutting Tool Materials

- Selection of Carbide to machine the work-part

- Identification System For Indexable Inserts

- Work-Part Materials

- Machinability and the specific cutting force

- Machinability of the Certain Material Evaluations

- Cutting Forces and Chip Formations

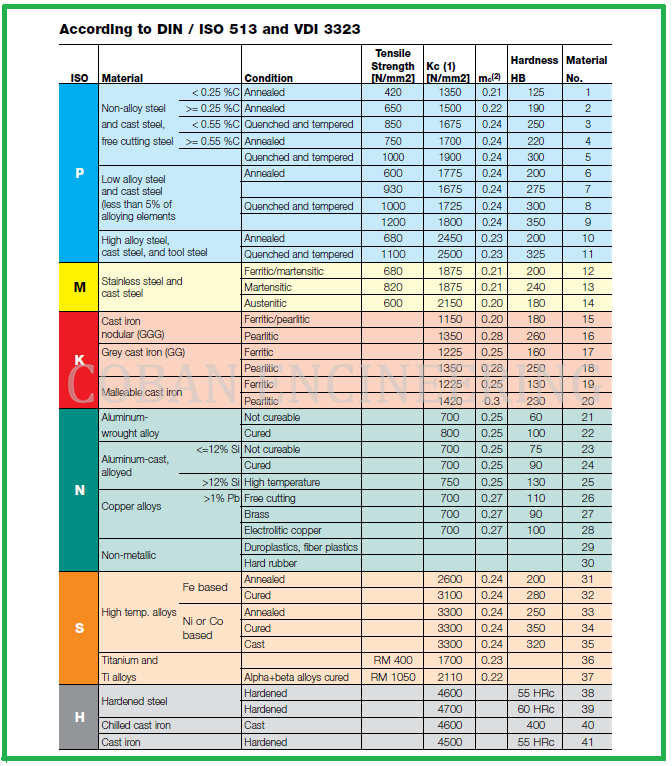

Material Group According to DIN / ISO 513 and VDI 3323

Material Group According to DIN / ISO 513 and VDI 3323

Machinability

Machinability describes the totality of all properties of a material that influence the machining process. Machinability is a characteristic of a material, such as a metal, that makes it easy to mill, turn, drill, shape, cut, grind, etc. Machinability can be difficult to predict because machining has so many variables. Two sets of factors are the condition of work materials and the physical properties of work materials. The condition of the work material includes eight factors: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength, and tensile strength. Physical properties are those of the individual material groups, such as the modulus of elasticity, thermal conductivity, thermal expansion, and work hardening. Other important factors are operating conditions, cutting tool material and geometry, and the machining process parameters ( the main material group, chip formation and removal, specific cutting forces, design of the cutting adge of cutting tools, cutting tool materials and cutting tool wear.)

Copyright ©2010-2023 Coban Engineering.All Rights Reserved.