- GD&T

GENERAL DIMENSIONING- International Paper Size Standards

- Technical Drawing Styles

- ISO And ANSI Projections

- ANSI Technical Drawing Views

- Technical Drawing Dimesioning Types

- ANSI and ISO Geometric Tolerancing Symbols

- Geometric Tolerancing Reading

- Taylor Principle Rule#1

- Form Tolerances

- Profile Tolerances

- Orientation Tolerances

- Location Tolerances

- Runout Tolerances

- TOLERANCES

ANSI AND ISO- Tolerancing and Engineering Standards

- Hole and Shaft Basis Limits And Fits

- ISO International System For Limits And Fits

- International Tolerance Grade (IT)

- Fundamental Deviations For Hole and Shaft Basis

- ISO Tolerance Band IT01-IT16

- Calculation Of International Tolerance

- Calculation of Upper and Lower Deviation For Shaft

- Calculation of Upper and Lower Deviation For Holes

- ISO Shaft Tolerances (3mm-400mm)

- ISO Shaft Tolerances (400mm-3150mm)

- ISO Hole Tolerances (3mm-400mm)

- ISO Hole Tolerances (400mm-3150mm)

- ANSI Standard Limits and Fits

- METAL CUTTING TECHNOLOGIES

- Terms and Definitions of the Cutting Tools

- Cutting Tool Materials

- Selection of Carbide to machine the work-part

- Identification System For Indexable Inserts

- Work-Part Materials

- Machinability and the specific cutting force

- Machinability of the Certain Material Evaluations

- Cutting Forces and Chip Formations

ANSI And ISO Geometric Tolerancing Symbols

There are several standards available worldwide to describe the symbols and the rules. These are American Society of Mechanical Engineers, ASME Y14.5M-2009, (GD&T - Geometric Dimensioning and Tolerancing) and International Organization for Standardization, ISO/TC 213, (GPS - Geometrical Product Specification) and ISO/TC 10 Technical Product Documentation (see the ISO GPS Specifications and verification List). The ISO (GPS) standards are typically only address a single topic at a time.ISO/TC 213 is a technical committee that standardizes tolerancing and related metrological practices. ASME Y14.5M standard has the advantage of providing a fairly complete set of standards for GD & T in one document.

Geometric Tolerancing Reference Chart ASME Y14.5M And ISO/TC 213

| Tolerances | Characteristics | Symbols | Datum Needed |

Applicable Modifiers (RMS, LMC, MMC) |

| Form | Straightness |  | No | LMC or MMC can apply to feature of size |

| Form | Flatness |  | No | Does not apply |

| Form | Circularity |  | No | Does not apply |

| Form | Cylindricity |  | No | Does not apply |

| Profile | Line Profile |  | No | Does not apply |

| Profile | Surface Profile |  | No | Does not apply |

| Orientation | Perpendicularity |  | Yes | LMC or MMC can apply to feature of size |

| Orientation | Angularity |  | Yes | LMC or MMC can apply to feature of size |

| Orientation | Parallelism |  | Yes | LMC or MMC can apply to feature of size |

| Location | Symmetry |  | Yes | RFS always |

| Location | Positional |  | Yes And No | LMC or MMC can apply to feature of size |

| Location | Concentricity |  | Yes | RFS always |

| Runout | Circular Runout |  | Yes | RFS always |

| Runout | Total Runout |

| Yes | RFS always |

Additional Geometric Tolerancing Symbol Chart ASME Y14.5M And ISO/TC 213

| Description | Symbols | References | |

| Max Material Condition (MMC) |  | ISO 2692/ASME | |

| Least Material Condition (LMC) |  | ISO 2692/ASME | |

| Regardless Of Feature Size (RFS) |  | ISO/ASME | |

| Spherical Diameter (SD) |  | ISO/AMSE | |

| Radius |  | ISO/ASME | |

| Diameter |  | ISO/ASME | |

| Envelope Requirement |  | ISO/ASME | |

| Free State Condition(Non Rigid Parts) |  | ISO 10579/ASME | |

| Minor Diameter |  | ISO/ASME | |

| Major Diameter |  | ISO/ASME | |

| Pitch Diameter |  | ISO/ASME | |

| Common Zone |  | ISO/ASME | |

| Exact Dimension |  | ISO/ASME | |

| Dimension Origin |

| ISO/ASME | |

| All Round (Profile) |

| ISO NONE/ASME | |

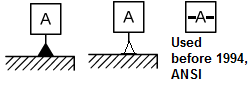

| Datum Feature Indication |

| ISO/ASME | |

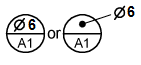

| Datum Target Indication |

| ISO 5459 | |

| Projected Tolerance Zone |

| ISO 10578/ASME |

Copyright ©2010-2023 Coban Engineering.All Rights Reserved.