- GD&T

GENERAL DIMENSIONING- International Paper Size Standards

- Technical Drawing Styles

- ISO And ANSI Projections

- ANSI Technical Drawing Views

- Technical Drawing Dimesioning Types

- ANSI and ISO Geometric Tolerancing Symbols

- Geometric Tolerancing Reading

- Taylor Principle Rule#1

- Form Tolerances

- Profile Tolerances

- Orientation Tolerances

- Location Tolerances

- Runout Tolerances

- TOLERANCES

ANSI AND ISO- Tolerancing and Engineering Standards

- Hole and Shaft Basis Limits And Fits

- ISO International System For Limits And Fits

- International Tolerance Grade (IT)

- Fundamental Deviations For Hole and Shaft Basis

- ISO Tolerance Band IT01-IT16

- Calculation Of International Tolerance

- Calculation of Upper and Lower Deviation For Shaft

- Calculation of Upper and Lower Deviation For Holes

- ISO Shaft Tolerances (3mm-400mm)

- ISO Shaft Tolerances (400mm-3150mm)

- ISO Hole Tolerances (3mm-400mm)

- ISO Hole Tolerances (400mm-3150mm)

- ANSI Standard Limits and Fits

- METAL CUTTING TECHNOLOGIES

- Terms and Definitions of the Cutting Tools

- Cutting Tool Materials

- Selection of Carbide to machine the work-part

- Identification System For Indexable Inserts

- Work-Part Materials

- Machinability and the specific cutting force

- Machinability of the Certain Material Evaluations

- Cutting Forces and Chip Formations

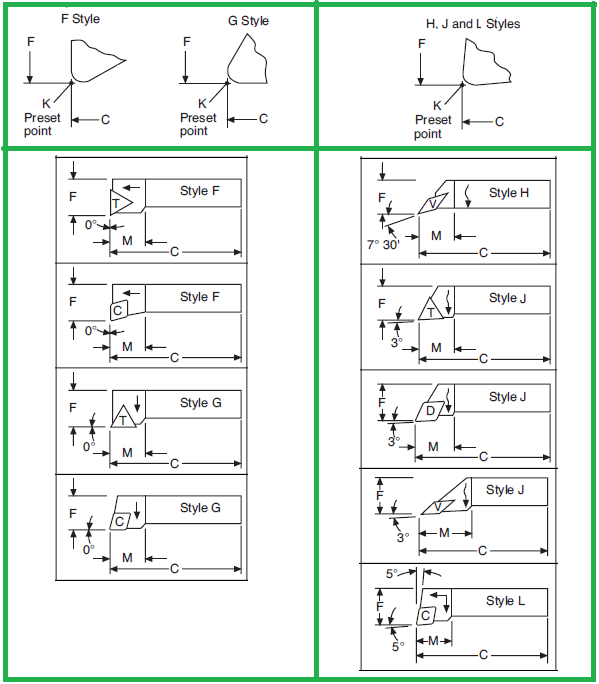

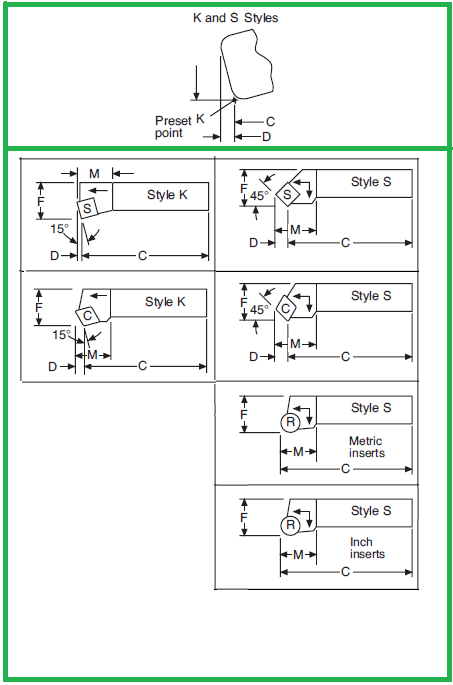

Indexable Insert Holder Application Guide for F, G, H, J, L, K. and S

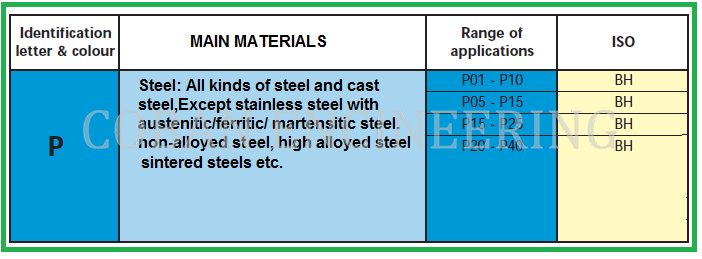

WORK-PART MATERIALS

The metal cutting industry produces an extremely wide variety of components machined from many different materials. Each material has its own unique characteristics that are influenced by the alloying elements, heat treatment, hardness, etc. These combine to strongly influence the choice of cutting tool geometry, grade and cutting data. Therefore, work-piece materials have been divided into six major groups, in accordance with the ISO-standard, and each group has unique properties regarding machinability (ISO DIN 513):

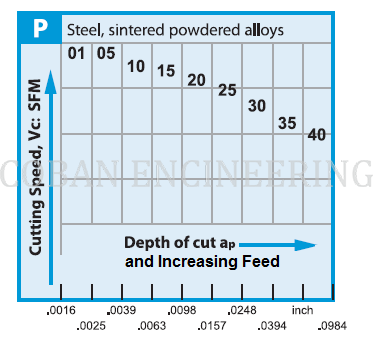

ISO - P:

Steel is the largest material group in the metal cutting area, ranging from unalloyed to high-alloyed material, including steel castings and ferritic and martensitic stainless steels. The machinability is normally good, but differs a lot depending on material hardness, carbon content, etc. This group includes long-chipping ferrous metals except stainless and austenitic steels and is, according to the cutting load, divided into the application groups 01-50.

Copyright ©2010-2023 Coban Engineering.All Rights Reserved.