- GD&T

GENERAL DIMENSIONING- International Paper Size Standards

- Technical Drawing Styles

- ISO And ANSI Projections

- ANSI Technical Drawing Views

- Technical Drawing Dimesioning Types

- ANSI and ISO Geometric Tolerancing Symbols

- Geometric Tolerancing Reading

- Taylor Principle Rule#1

- Form Tolerances

- Profile Tolerances

- Orientation Tolerances

- Location Tolerances

- Runout Tolerances

- TOLERANCES

ANSI AND ISO- Tolerancing and Engineering Standards

- Hole and Shaft Basis Limits And Fits

- ISO International System For Limits And Fits

- International Tolerance Grade (IT)

- Fundamental Deviations For Hole and Shaft Basis

- ISO Tolerance Band IT01-IT16

- Calculation Of International Tolerance

- Calculation of Upper and Lower Deviation For Shaft

- Calculation of Upper and Lower Deviation For Holes

- ISO Shaft Tolerances (3mm-400mm)

- ISO Shaft Tolerances (400mm-3150mm)

- ISO Hole Tolerances (3mm-400mm)

- ISO Hole Tolerances (400mm-3150mm)

- ANSI Standard Limits and Fits

- METAL CUTTING TECHNOLOGIES

- Terms and Definitions of the Cutting Tools

- Cutting Tool Materials

- Selection of Carbide to machine the work-part

- Identification System For Indexable Inserts

- Work-Part Materials

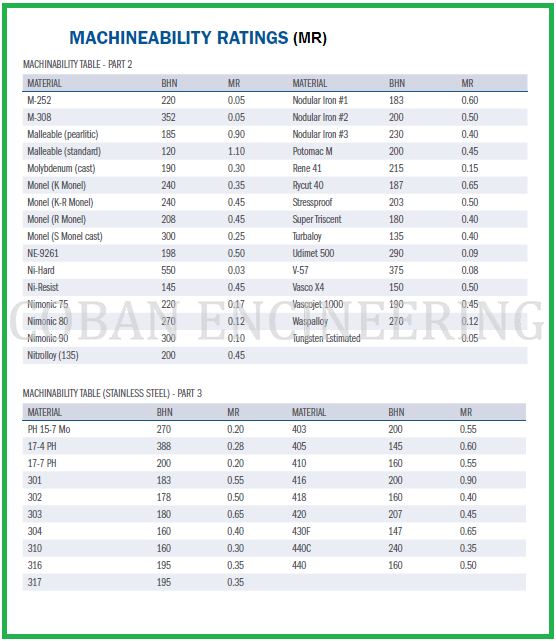

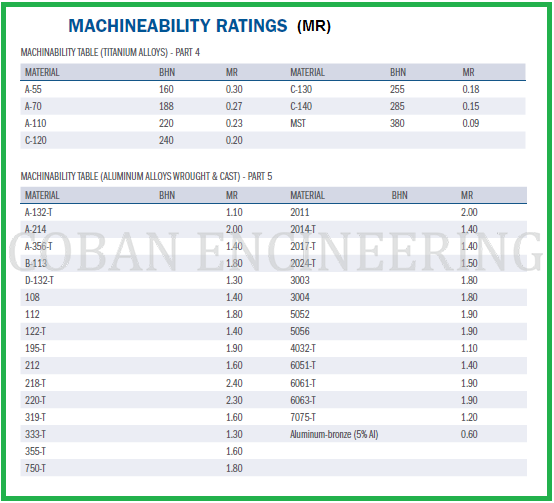

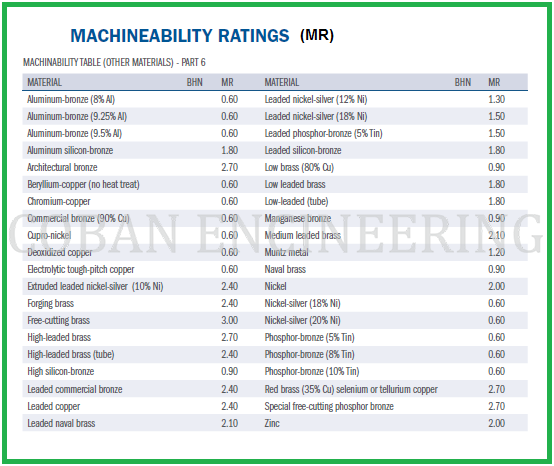

- Machinability and the specific cutting force

- Machinability of the Certain Material Evaluations

- Cutting Forces and Chip Formations

Machinability advantages come from percentages carbon content and additives in the steel. The Grades of plain carbon steel is identified by a 4-digit number. The first two digits identify whether sulfur or phosphorus has been added to improve machinability. They can also represent other elements that may have been added to improve heat treat response or other properties. the second two digits are carbon content multiplied 100%. As an example 1010 Steel is plain carbon steel and has 0.10% carbon content in the steel. A1212 steel is grade that has been resulfurized and rephosphorized to improve machinability and has 0.12% carbon content in the material. A 4140 steel contains Ni, Cr and Mo and has 0.40% carbon in the material. When lead (Sn) is added to steel, the grade designated has an "L" letter between the first and second set of digit that will show us that it is lead-alloy steel. As an example; 12L14 steel has been resulfurized and rephosphorized and additions added lead. The carbon content in the steel is 0.14%. Manganese, sulfides and lead make steel easily machine which is called free machining.

WORK-PIECE MATERIAL CONDITIONS

The physical properties and the conditions of the work-piece material have direct effect on its machinability. The various characteristics and conditions described as conditions of the work-piece material, individually and in combinations, directly effect and determine machinability. The following factors determine the condition of the work-piece material: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength and tensile strength.

Microstructure: The microstructure of a metal refers to its crystal or grain structure as shown through examination of etched and polished surfaces under a microscope. Metals whose microstructures are similar have like machining properties. But there can be variations in the microstructure of the same work-piece that will affect machinability.

Grain Size: Grain size and structure of a metal serve as general indicators of its machinability. A metal with small undistorted grains tends to cut easily and finish easily. Such a metal is ductile, but it is also "gummy." Metals of an intermediate grain size represent a compromise that permits both cutting and finishing machinability. Hardness of a metal must be correlated with grain size and it is generally used as an indicator of machinability.

Heat Treatment: To provide desired properties in metals, they are sometimes put through a series of heating and cooling operations when in the solid state. A material may be treated to reduce brittleness, remove stress, to obtain ductility or toughness, to increase strength, to obtain a definite microstructure, to change hardness or to make other changes that affect machinability.

Copyright ©2010-2023 Coban Engineering.All Rights Reserved.